5 Reasons Why Inline Safety Relief Valve Testing is the Most Reliable Testing Method

Reliable testing of your safety relief valves is paramount. As their name suggests, safety relief valves keep your facility safe. In the event that something happens in your system, a safety relief valve releases excess pressure, avoiding damage to your machinery and system, and helping keep your employees and your facility safe. Since these valves are so important, you need to know that they’re functioning properly. That means accurate testing you can trust. While there are a range of testing methods on the market, here are just five reasons that in-line safety relief valve testing is the most reliable testing method available to your facility:

#1 Removes Potential for Human Error

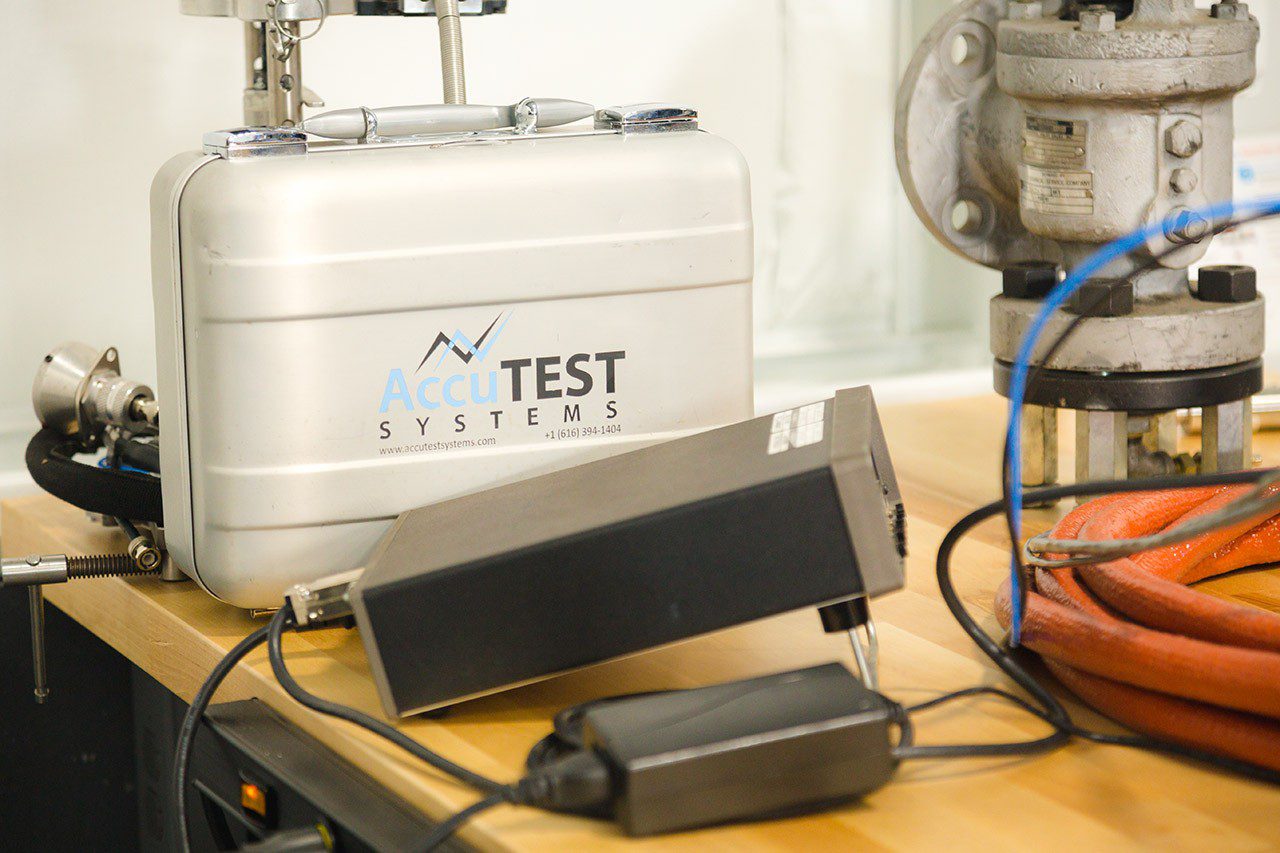

Quality in-line safety relief valve testing like the AccuTEST system eliminates the potential for human error when testing valves. Traditional bench testing requires that someone remove and replace each individual valve, and hydraulic in-line testing relies on a hand pump to test valves. Both of these methods allow for a significant range of human error. With an electric motor system like AccuTEST, valves are tested in-line. A software-controlled electric motor applies constant, steady pressure just until a valve simmers and captures the precise set point. This removes the potential for human error, providing your technicians with the accurate reporting they need to do their jobs well.

#2 Offers Real-Time, In-System Reporting

If you’re looking for reliable results from your valve testing method, in-line again offers another advantage. There’s no need to remove valves and test them in a facility somewhere. Instead, with in-line testing equipment, valves are tested in your system, so you can see exactly how they are functioning within your facility.

This gives technicians better insight into your valves and your system. Since the technician is evaluating the valve in-line, they can also see if the valve is misaligned, the wrong size, or improperly installed — all factors that you can’t assess with off-site or bench valve testing.

#3 Results are Repeatable and Accurate

In-line safety valve testing is both exceptionally accurate and repeatable. For example, when you test a valve with the AccuTEST system, you’re going to get the same results even after multiple tests. This helps a) ensure your testing is accurate, and b) minimizes the time it takes to complete testing. Technicians don’t have to worry about the validity of the results or wonder if that was a relevant readout. One test and they’re done. They can make adjustments knowing they have the most reliable data available.

#4 Eliminates Transportation-Related Damage

When valves are removed from your system and transported to and from a testing facility, there’s a significant potential for damage. Jostling around in a truck isn’t good for the equipment, and can affect the valves even after they’ve been tested at the facility. This means that the results you get from the testing facility aren’t always accurate once the valve has been re-installed in your facility.

There’s an added concern about the actual re-installation of the valves as well. If they are installed improperly or have sustained any damage over the course of transportation, you won’t have the fully functioning safety release valves you need to keep your facility safe.

#5 Ensures Production Can Continue

In-line testing eliminates the need for full-system downtime. Not only do you get accurate, repeatable results that you can trust, but you also don’t have to shut down production. When you test safety relief valves in-line, you’re able to keep your system running, which makes testing more affordable and more efficient. Quality, reliable valve testing needs to be both accurate and convenient. In-line safety relief valve testing is one of the only testing options to deliver both.

In-line safety relief valve testing is one of the most reliable testing methods on the market today. Exceptional accuracy, repeatable results, and of course the fact that you don’t need to shut down production are just a few of the reasons to choose in-line testing whenever possible.

If in-line testing seems like the most reliable, cost-effective testing option for your company, let us know. AccuTEST has developed the highest-quality portable in-line testing system on the market. Give us a call at 616-349-1401 or set up a live webinar demo to see our system in action today!