Hydraulic vs. Electronic Pressure Relief Valve Testing System

When it comes time to find a new inline pressure relief valve testing system, one of the biggest differences in the systems you’ll see on the market is hydraulic vs. electronic systems. When we talk about hydraulic pressure relief valve systems, we’re talking about the systems that use a hand pump to apply the lifting force. Operators use the hand pump to slowly increase pressure on the safety valve, and once the pressure builds up to the setpoint, the valve releases.

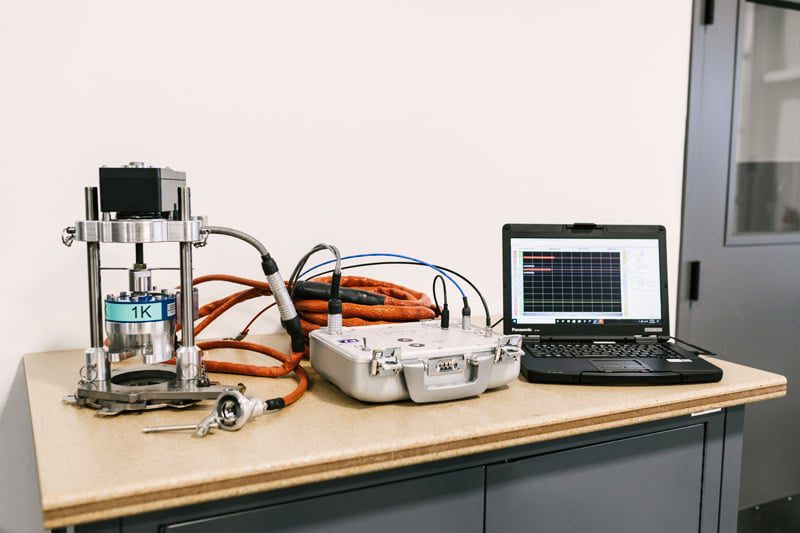

Electronic systems function similarly, but use a software-controlled electric motor, rather than hydraulics, to build up pressure and take a reading once that pressure relief valve begins to open.

While both methods work to test safety relief valves, there are significant differences between the two options. We’re going to compare both testing system types against each other in three important categories: precision & accuracy of results, the weight of the system, and ease of use, to give you a better idea of which system is best for your company. Let’s start with what matters most, the results:

Precision & Accuracy of Results

Accurate, repeatable results are what you’re looking for. Electronic pressure relief valve testing systems deliver exactly that, with incomparable precision. This is because an electronic system makes use of precisely controlled electric motor that consistently builds pressure on the valve, and then accurately reads out results at the exact point when the valve releases pressure.

Conversely, a hydraulic system’s results are dependent on the operator. Since pressure is added using a hand pump, results can vary from operator to operator depending on how quickly they pump the hydraulic system. This presents a significant opportunity for human error. Not only could a number of operators all get different results on one valve, but even the same operator could get different results after running two tests on the same valve. Since every operator may get different results based on the rate that they’re pumping the hand pump, results from a hydraulic system aren’t always repeatable.

Weight of the System

Hydraulic pressure relief valve testing systems are notoriously heavy. In order for the hydraulic system to function properly, the system needs a long length of bulky hydraulic hose. This increases the size of the system overall and makes it difficult to carry around, especially in tight-quartered facilities where pressure relief valves can be hard to reach.

Electronic pressure relief valve testing systems, on the other hand, are exceptionally compact and feature reduced bulk. AccuTEST’s system, for example, is one of the most portable— able to fit right into a standard-sized backpack. This makes it easy for one operator to carry around safely.

Ease of Use: Hydraulic vs. Electronic

The easier it is to use pressure relief valve testing equipment, the more jobs your technicians can complete, in less time. Again here, hydraulic testing systems present a few additional problems. Their hydraulic hoses are full of hydraulic fluid that not only adds weight but that also make the testing process more difficult.

Hydraulic fluid is messy, and if anything happens to one of the hoses, your operators will be cleaning up spills instead of completing more jobs. Additionally, it’s difficult to get a consistent, continual line of fluid in hydraulic hoses, especially when they’re being carried around large facilities. If there are air gaps in the hydraulic hose, they will cause a change in the readings you get, which means inaccurate results, and more work for your operators.

Electronic pressure relief valve testing systems aren’t hindered by hydraulic hoses and fluid. They’re compact, easy to carry, and even easier to use. For example, the AccuTEST equipment makes use of an exceptional One-Touch Testing feature. Instead of having to wrangle hydraulic hoses and operate a hand pump, operators need only connect the much lighter cable harness and press the “start” button once the electronic pressure relief valve testing system is in place. The system does its job and delivers an accurate, repeatable result.

When compared side by side, it’s easy to see that electronic pressure relief valve testing systems beat out hydraulic systems in every category. They’re more compact, easy-to-use, and most importantly, they offer precise, accurate, and repeatable results. If you’re looking to upgrade your testing equipment, or if you’re just looking into inline safety relief valve testing equipment, an electronic system is always the way to go.

For more information about electronic pressure relief valve testing systems, or the AccuTEST system itself, get in touch. We offer live demos that let you see exactly how our system works, and we can answer any questions you might have in real-time.