3 Reasons to Consider Adding Inline Testing to Your Pressure Relief Valve Testing Schedule

Pressure relief valves are an integral component of your facility’s system. While you must adhere to a regular, mandated testing schedule, bench testing isn’t always required for those tests. Whenever possible, implementing inline testing provides your facility with a more efficient, economical, and accurate testing method. Here are just a few reasons to consider adding inline testing to your pressure relief valve testing schedule.

Test Valves Under Normal Operating Conditions

When inline testing is an acceptable method for your required testing schedule, it’s good to know that it does provide you with a more realistic, accurate representation of how your pressure relief valves are working in your facility.

Bench tests can only tell you how a valve is functioning in a testing lab, after being removed and jostled around in transportation before being tested. Inline testing gives you real-time information on how your valves are functioning within your system, under normal operating conditions. This improves your insight into your system, and ensures you’re getting the most accurate results possible.

Improved Technician Safety

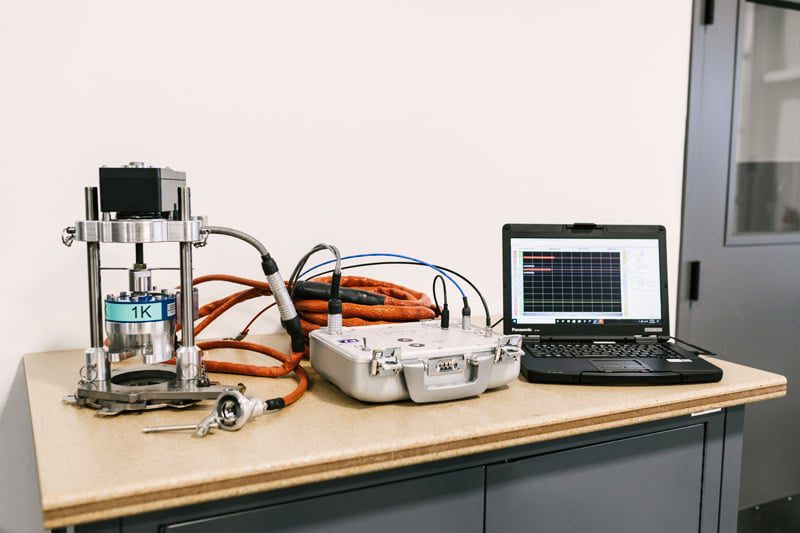

Inline testing, especially when done with advanced pressure relief valve testing equipment, is much safer for technicians. Instead of climbing around your plant locating, disassembling, and removing each and every safety valve, they can safely and efficiently test the valves in place using a load rig and testing equipment designed to handle the pressure behind each valve.

Removing valves for testing can certainly be done safely, but it does present additional risks to technicians, since there are significantly more steps, more parts to be removed, and more opportunities for something to go wrong. Inline safety valve testing is much safer for operators to complete.

Affordable, Economic Testing Solution

Perhaps the greatest benefit of inline valve testing equipment is that you can complete your required testing and receive accurate and repeatable results, without the cost associated with plant downtime and extra manpower. New, high-tech inline valve testing systems can be operated by just one technician, and because you’re running pressure relief valve tests inline, you don’t need to pause your facility’s operations or cause downtime to complete the testing.

All of these benefits combined ensure you’re getting the information you need on your system, in a way that’s affordable, without the costly and time-consuming process of removing each and every valve while your system is down.

AccuTEST’s testing equipment systems make it easy to test all of your pressure relief valves, without total downtime. Our equipment is easily handled by just one technician and can calculate set pressure with 0.5% accuracy, ensuring your pressure relief valves are always working exactly how they should. For more information about the AccuTEST system, get in touch.