3 Signs Of Pressure Relief Valve Failure

In the manufacturing industry, we’re taught to look at the big picture when it comes to troubleshooting. If a pressure relief valve experiences failure, is releasing pressure before a system reaches maximum pressure, or is constantly leaking or chattering, it’s always best to assume that there’s something wrong with the system.

When maintained properly, a pressure relief valve can stay in service for up to 30 years, and if you’ve been having your valves tested regularly, it’s likely that there’s something else in your system that’s to blame. That said, pressure relief valves can and do fail, and it’s important to be able to recognize the signs in order to quickly solve the problem, and keep your facility safe. Here are 3 signs of pressure relief valve failure to watch for when you’re troubleshooting your facility’s system:

1. System Cannot Reach Pressure

If your system isn’t reaching pressure, this could be a sign of pressure relief valve failure. In some cases, this could be fixable.

Causes for “System is Over Maximum Pressure”

If the valve was calibrated to the wrong set pressure, it could simply be releasing early. This happens occasionally when changes are made to your facility’s plant design, and technicians forget to recalibrate pressure relief valves for the system’s new normal operating pressure. Your valve technicians can adjust the valve’s set pressure to address this issue.

If that doesn’t solve the problem, and all other aspects of your system seem to be functioning properly, then it’s possible that your pressure relief valve needs to be changed. After years of service, the valve could have become damaged or eroded by dirt and debris in the environment, blocking the valve from fully closing. This often causes chattering, where the valve isn’t fully open, but is opening and closing rapidly. This prevents the valve from operating properly.When your system cannot reach pressure, you’ll likely experience production slowdowns, if not total downtime. It’s good to know that checking your pressure relief valves can help you avoid costly downtime.

2. System is Over Maximum Pressure

Pressure relief valves and pressure safety valves are what keep your facility safe. Relief valves keep the system at the optimal pressure to avoid damaging pressure-sensitive components or machinery. In the event that your system builds up above the maximum pressure for safe operation, safety valves open to let off additional pressure, keeping your facility, your employees, and your equipment safe.

Causes for “System is Over Maximum Pressure”

If your system is above pressure and your pressure relief valves (PRVs) have not released, this is likely a functional pressure relief valve failure. Again, you’ll need to make sure that the valves are set to the correct set pressure, and you’ll want to take a look at the big picture of your system to understand why it’s functioning overpressure in the first place. Outside of those two concerns, if your pressure relief valves haven’t released, it’s likely that they’ve failed.

Contaminants, like dirt, lint, rust, sludge, or even the misalignment of the valve can cause the pressure relief valve to stick. At this point, you might see that your system is above pressure, or you’ll notice other pressure relief valves in the system releasing to make up for this valve’s malfunction.

3. Pressure Relief Valve is Leaking or Has No Pressure

While the other two signs are pretty obvious, this last sign is more noticeable when you’re directly inspecting your pressure relief valves. Leaking valves are a problem, and can contribute to slower, less efficient production, but they can also be more difficult to notice as their effect on the entire system can be much smaller.

This is one of the reasons that preventative valve testing and maintenance is so important. A relief valve is designed to maintain optimal pressure; if it’s leaking, your system cannot optimal pressure.

Causes for “Pressure Relief Valve is Leaking or Has No Pressure”

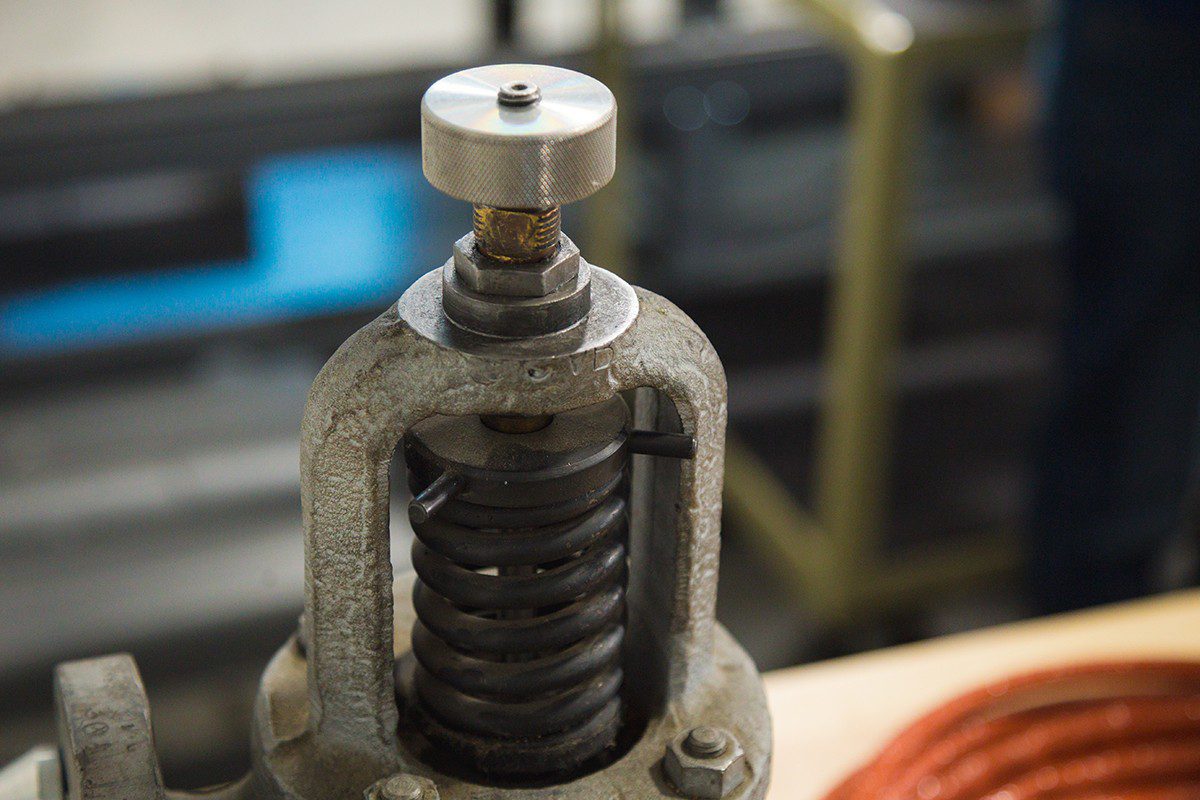

If your pressure relief valve has no pressure, it’s likely that the balance hole has become plugged, the spring is broken, or the valve simply has a loose fit. In the case of a loose fit or broken spring, replacement is a must. The valve isn’t able to function properly within your system, which means it’s not protecting your facility, your employees, or your equipment in the event that there is a larger problem.

Pressure valve leakage is a little more complicated to troubleshoot, as there are a variety of potential causes. It could be the valve itself, it could be that misalignment is causing a failure to reseat after a correct opening, or it could be that there is greater pressure in your system than the valve’s set pressure. This is where a quality inline valve testing system can help. Systems like the AccuTest SL and the AccuTest TT offer a leak check capability that allows you to specifically test for pressure leaks in your system.

Remember that a Malfunctioning Pressure Relief Valve Isn’t Always a Sign of Valve Failure

“A malfunctioning pressure relief valve is most often a symptom of a greater problem, rather than a problem itself.”

Summary: Three Common Signs Of Pressure Relief Valve Failure

To recap, there are three common indicators that your pressure relief valves are failing.

- Your system cannot reach pressure

- Your system is over maximum pressure

- A pressure relief valve is leaking or has no pressure

The greatest takeaway from this article should be that a malfunctioning pressure relief valve is most often a symptom of a greater problem, rather than a problem itself. As we mentioned earlier, pressure relief valves that are properly maintained can last for up to 30 years. In most cases, it’s important to look at the “why” behind pressure relief valve failure, rather than just replacing the valve in question.

Learn more about troubleshooting pressure relief valve failure

This article from the Journal of Emerging Technology and Advanced Engineering provides a helpful flowchart outlining the troubleshooting procedure to take in the event that you experience any sort of pressure relief valve failure.

Add a valve testing system from AccuTest

If your facility is having difficulty diagnosing a pressure relief valve failure, inline testing can help. Instead of removing the valve and either replacing it or sending it out for testing, use inline testing equipment like the AccuTest SL or the AccuTest TT to quickly and efficiently test your pressure relief valve and safety valves. You’ll get accurate, real-time results, helping your facility return to optimal performance quickly, and safely.

For more information about AccuTEST valve testing systems, download our product guide, give us a call at 616-394-1401, or request a live demonstration!